Misaligned mirrors are one of the common causes of reduced image quality in reflecting telescopes, but one that can be solved with collimation.

It is true that there are a number of commercially available accessories that will generate artificial stars for this exact purpose.

However, most of these systems only work over long distances, sometimes up to 30m, which probably means an outdoor session unless you are lucky enough to have access to a large outbuilding or an unused warehouse.

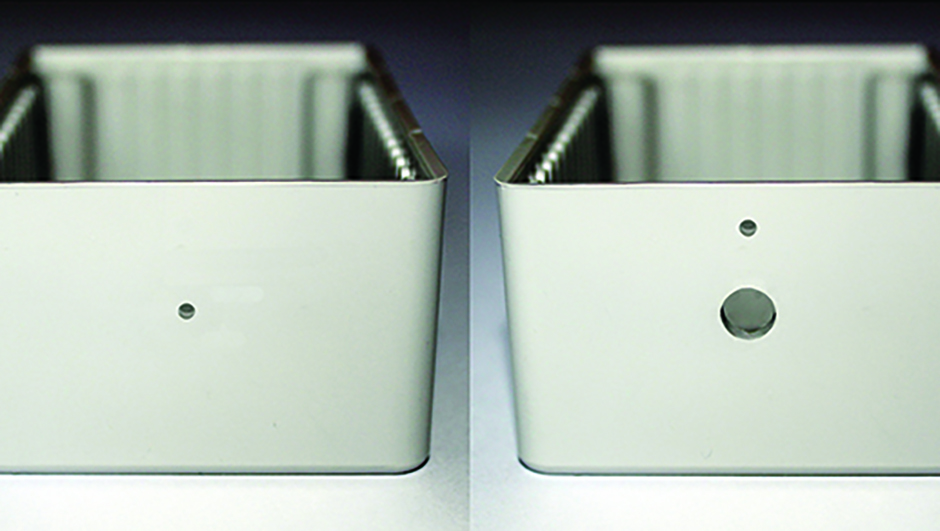

The principle behind our DIY adaptation is that it can be used indoors at a distance of less than 7m – thereby making it possible to set up a test range in a hallway or a large living room.

Tools - Long nose pliers and ‘mini’ wire cutters, wire strippers, fine-tipped soldering iron, lead-free solder, junior hacksaw, electric drill and bits, needle file, bradawl, pocket multimeter.

Components- Solderless breadboard with at least 400 connection points; single-pole double-throw miniature toggle switch, 6A rated/12V DC compatible; 4.7kΩ linear rotary potentiometer with plain or splined shaft and a control knob; two resistors, one 270Ω ±1% tolerance and the other 2.2 kΩ ±5% tolerance; one 5mm round white superbright (20,000mcd intensity) LED and one 3mm round red LED, each 20-30mA rated.

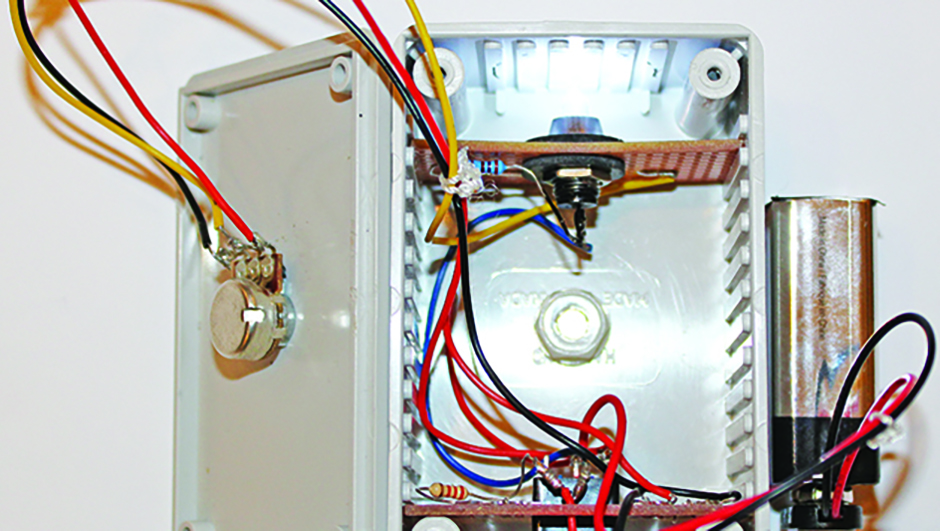

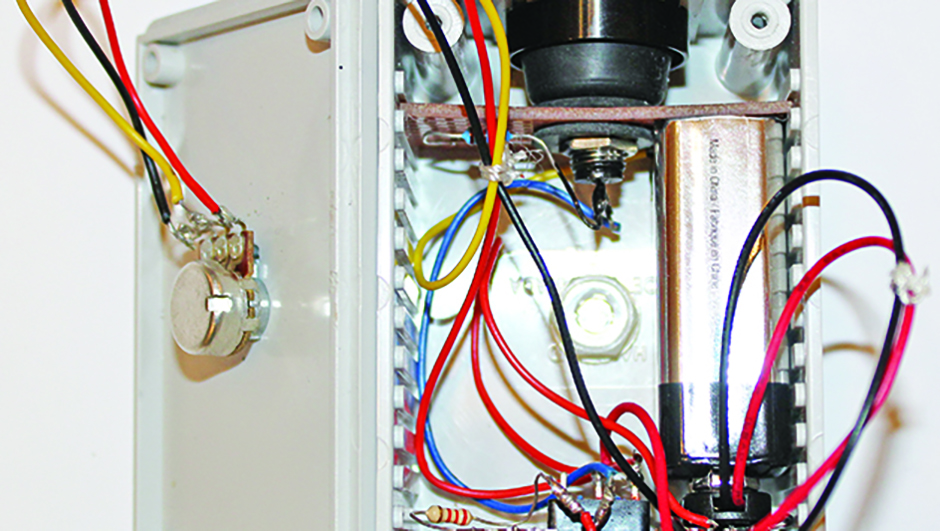

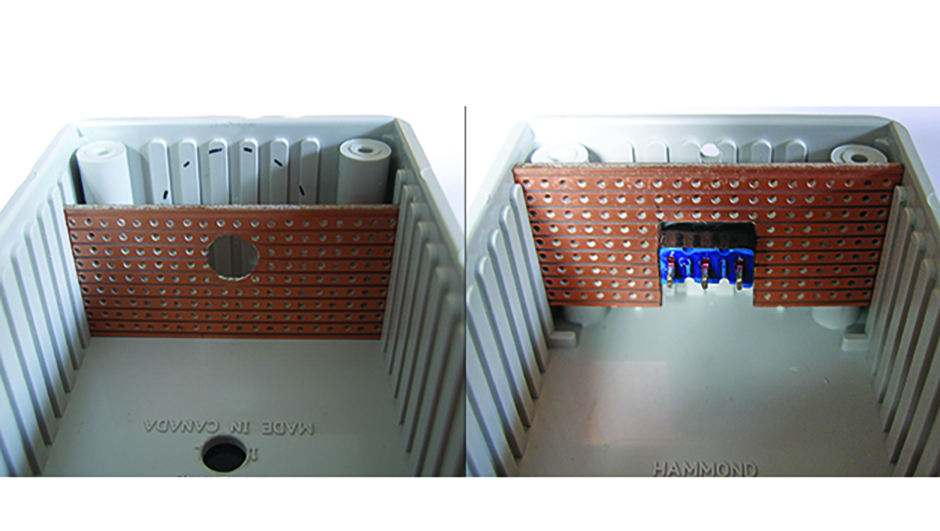

Electronics- Project box with integral PCB guides, two stripboards to suit inner box depth, precision 10µm pinhole in mount, 5mm LED bezel mount, 16/0.2mm 3A stranded equipment wire, plus the components from part one.

Sundries- Fuse wire (5- and 15-amp); jumper wires with insulated solid tips (various colours and lengths); 9V long-life battery and snap on lead; double-sided foam tape for switch and battery attachment to the breadboard, insulating washers and tape, small ‘seat buffer’ to retain pinhole mount, cardboard disc to simulate mount diameter, marker pen, methylated spirit, dust mask, safety goggles, lacing cord or similar.

The task itself requires only minimal electronics knowledge and assembly skills.

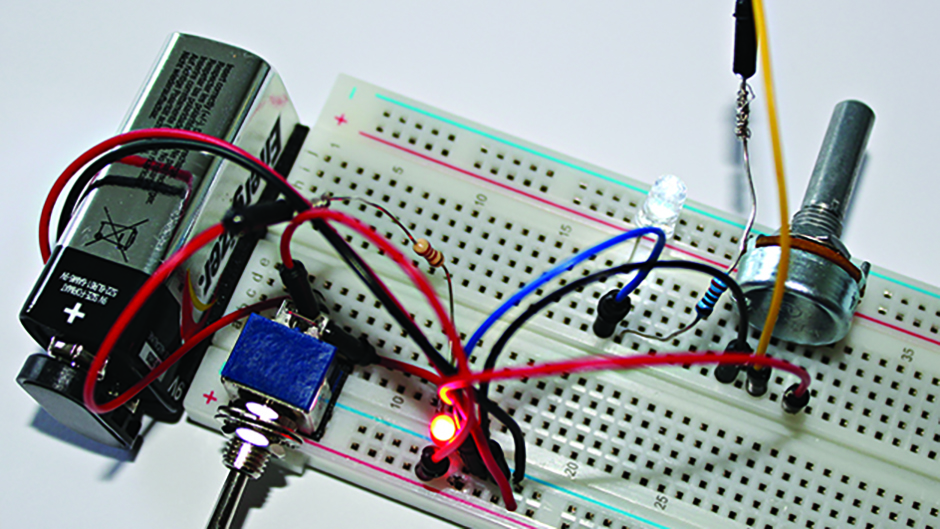

At the end of your endeavours you will have built your own star simulator with which you will be able to reveal diffraction circles and bright centre spots to rival the star patterns shown in your scope’s user manual.

All of the parts required to build the simulator are easily available either online or from electronics stockists.

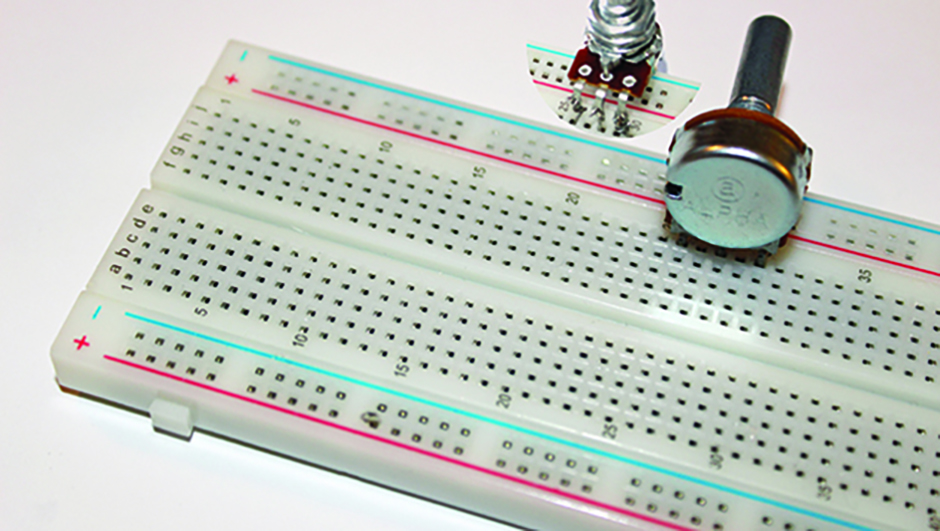

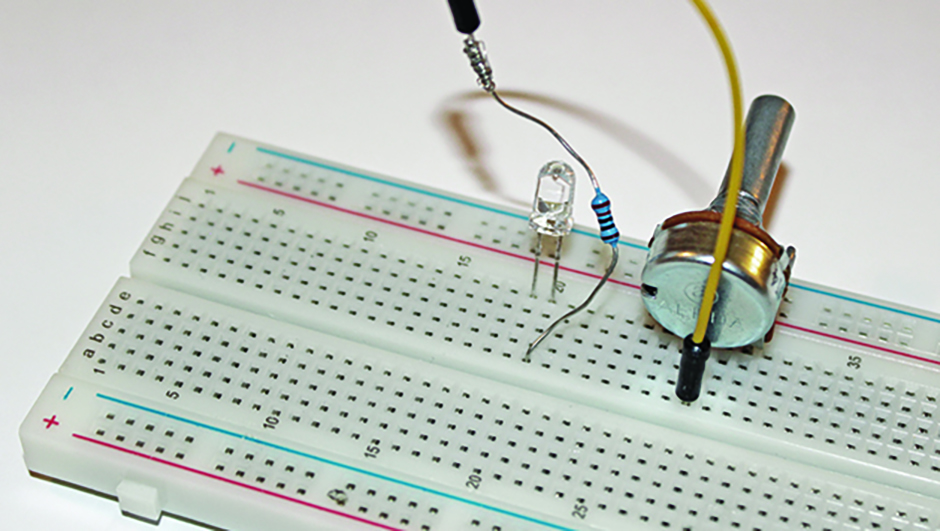

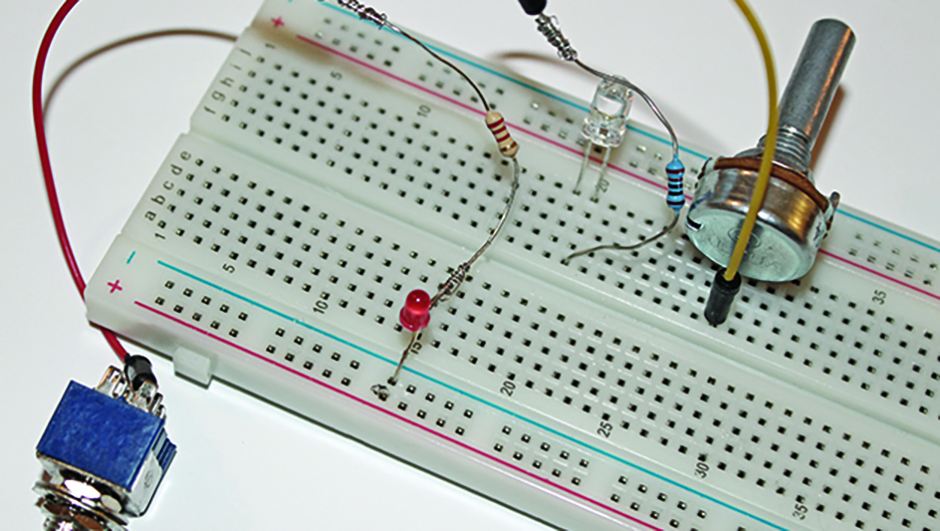

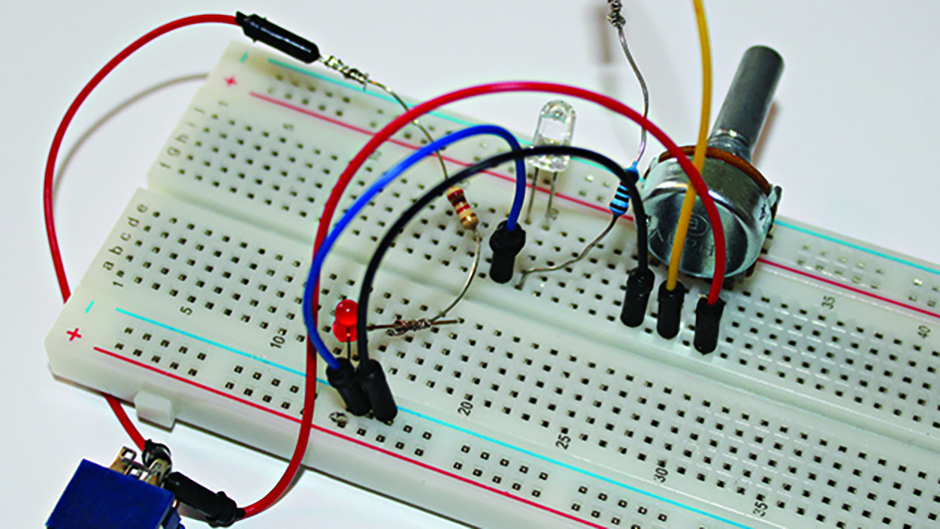

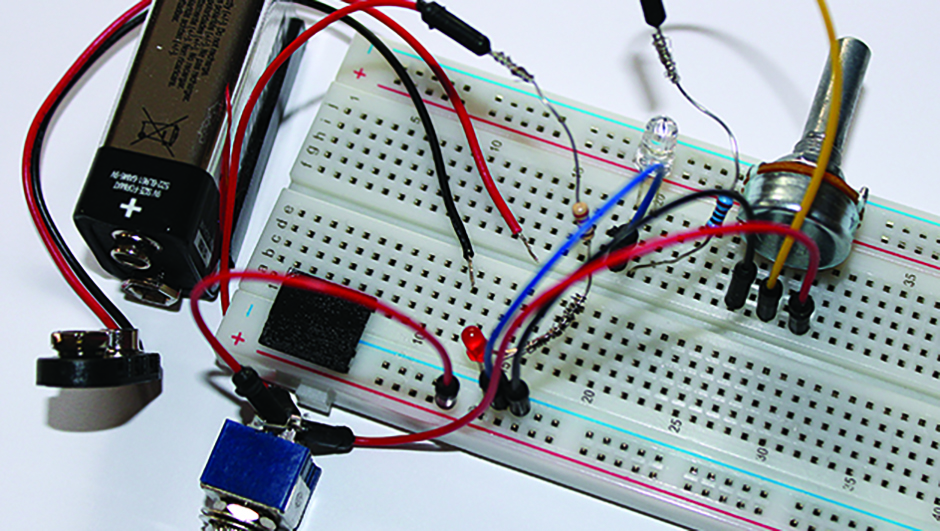

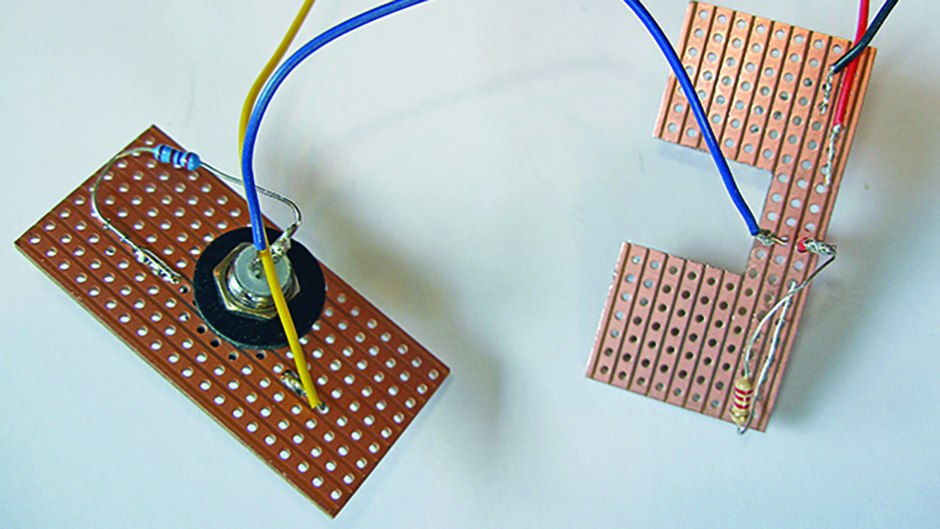

The circuitry is not complicated, but even so it’s a good idea to build a test setup on what is known as a ‘breadboard’ to check the arrangement of the components and to confirm everything functions correctly before you begin assembly.

First we’re going to focus on the star simulator’s circuitry using a solderless breadboard in readiness for test and transfer to the final control box.

Using a breadboard allows components to be placed and moved between sets of spring contacts, and also means you can try out your own circuits to improve performance.

For our purposes we used a double-pole double-throw (DPDT) switch with six terminals (of which only two were used).

You could alternatively use a single-pole double-throw (SPDT) version, which has three terminals with the centre ‘common’ and one ‘on’ connection being used.

To create a star...

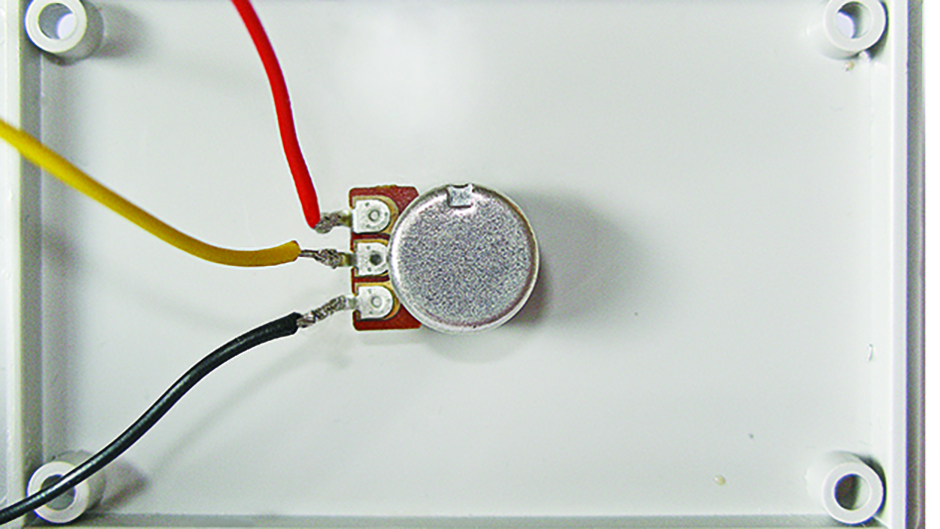

To vary the intensity of the ‘star’, you need one of two basic types of single turn potentiometer, which we’ve designated RPA1 & RPA2.

The RPA1 has three ‘finger’ terminals set 5mm apart, often with a longer round shank, ideal for use with a breadboard circuit.

The RPA2 usually has solder terminals with a knurled shank.

For our project we used an RPA1, but if you have an RPA2 you can still attach it using short lengths of 15-amp fuse wire with one end bent through each eyelet in the angled terminals and bound with 5-amp wire to ensure good electrical contact.

The other (straight) end can then be adjusted to plug into the breadboard as with an RPA1.

In both cases the shank is usually 6mm in diameter to accept a control knob.

The light comes from LEDs, which are low-current and low-resistance devices.

Their polarity is characterised by a positive long lead (anode) and a negative short lead (cathode).

To prevent burn out, a resistor is placed in series with each LED to limit the amount of current that flows through it.

The LED limiting resistor values as calculated for our circuit are available at the link at the top of this page.

OLYMPUS DIGITAL CAMERA[/caption]

OLYMPUS DIGITAL CAMERA[/caption]